Requesting Main Industry : Manufacture of electrical components

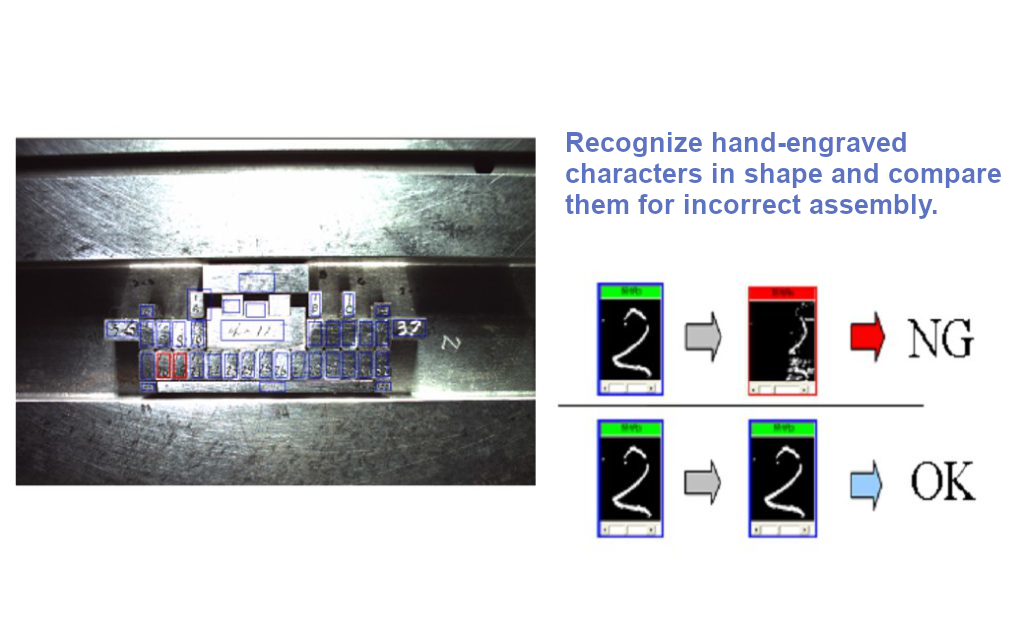

Incorrect assembly when overhauling the molding die should be prevented

Problems we had

After the mold was disassembled during overhaul, the assembly of the mold was visually checked for incorrect assembly when the mold was assembled. However, visually overhauling occurred and the mold was often molded in the wrong assembly state.

Solving Problems

Molding dies for connectors often have small die parts and multiple cavities that are molded together. When the dies are assembled, they are often assembled incorrectly. We have developed an image inspection machine exclusively designed to prevent incorrect assembly, although there was only a way to enhance visual checks in the past. The introduced customer was able to reduce the spill of the wrongly assembled dies to zero.

Introduced equipment

Other examples of introduction

Industry : Manufacture of electrical components

The continuous terminal in a small space is needed to be wound

Industry : Manufacture of electrical components