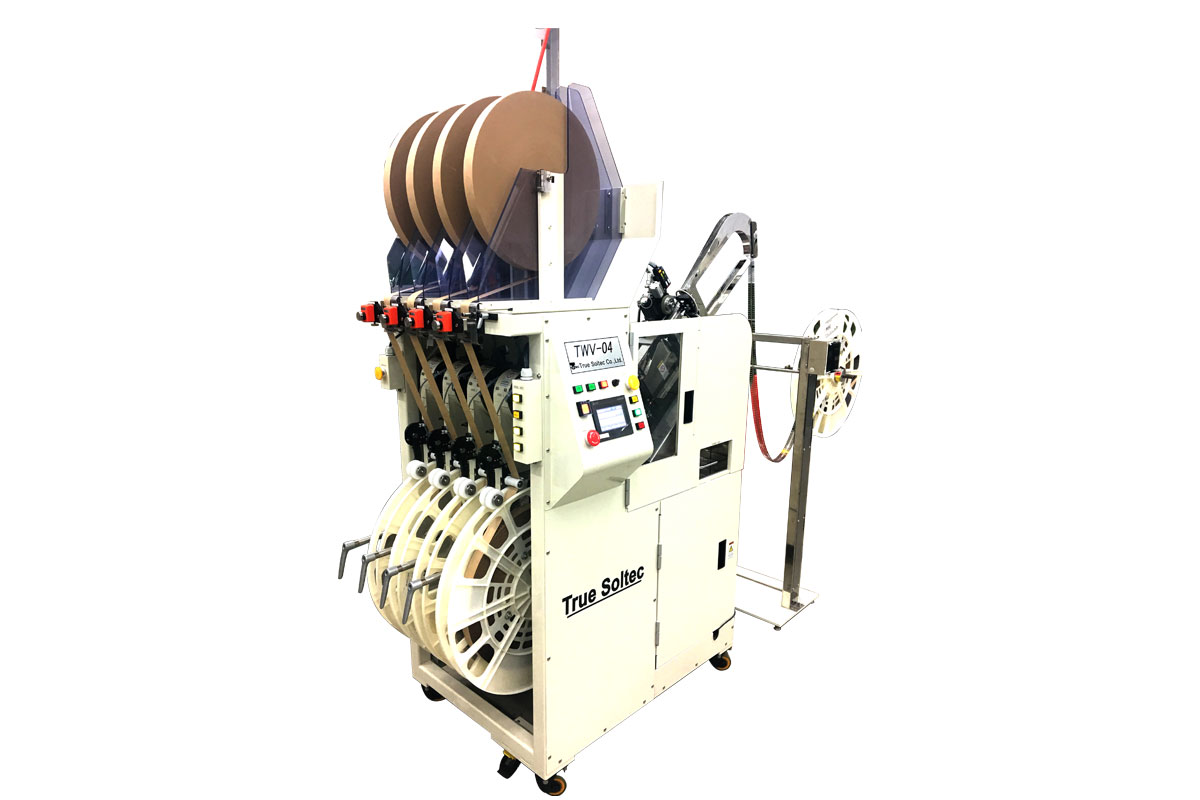

TWV-04 Automatic terminal winder for 1 row 4 reels

Product details

Space-saving design!

Conventional winder moves reel unit when its reel changing.

However, our newly developed winder moves feeding guide, not reel unit.

With this design, winder size turned to be smaller than conventional type and you can wind multiple reels at small area.

Accumulator is not needed!

Unlike the most of conventional winder, our winder does not have accumulator.

When the terminals are almost full wound, our winder start winding faster and terminal loop between press machine and winder become smaller, then winder moves terminal feeding guide to the next reel.

With this, our winder can finish reel changing very faster without using accumulator.

Safe and stable feeding with multi angle adjustable guide!

According to winding quantity, our winder adjusts angle of feeding guide so that terminals are wound stably with the same tension.

Easy usability!

In order to simplify the changeover, our winder has many useful functions such as one touch paper setting, visualized guide adjustment and parameterized production condition.

You can shorten the setup time and improve productivity.

Product catalog

Check out the video for more details!

Related products

TSJ-05

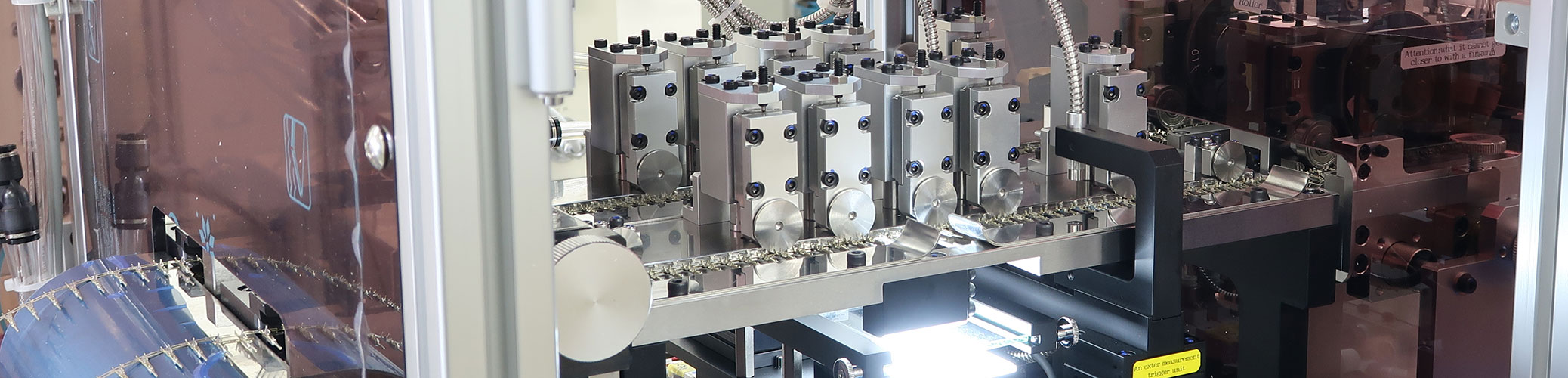

100% Inline Terminal Quality Inspection System

MOTER DRIVE

Crimp Terminal Transfer Device for All Inspection

Eye-M03

Match mark image inspection system for injection mold

BYW-02