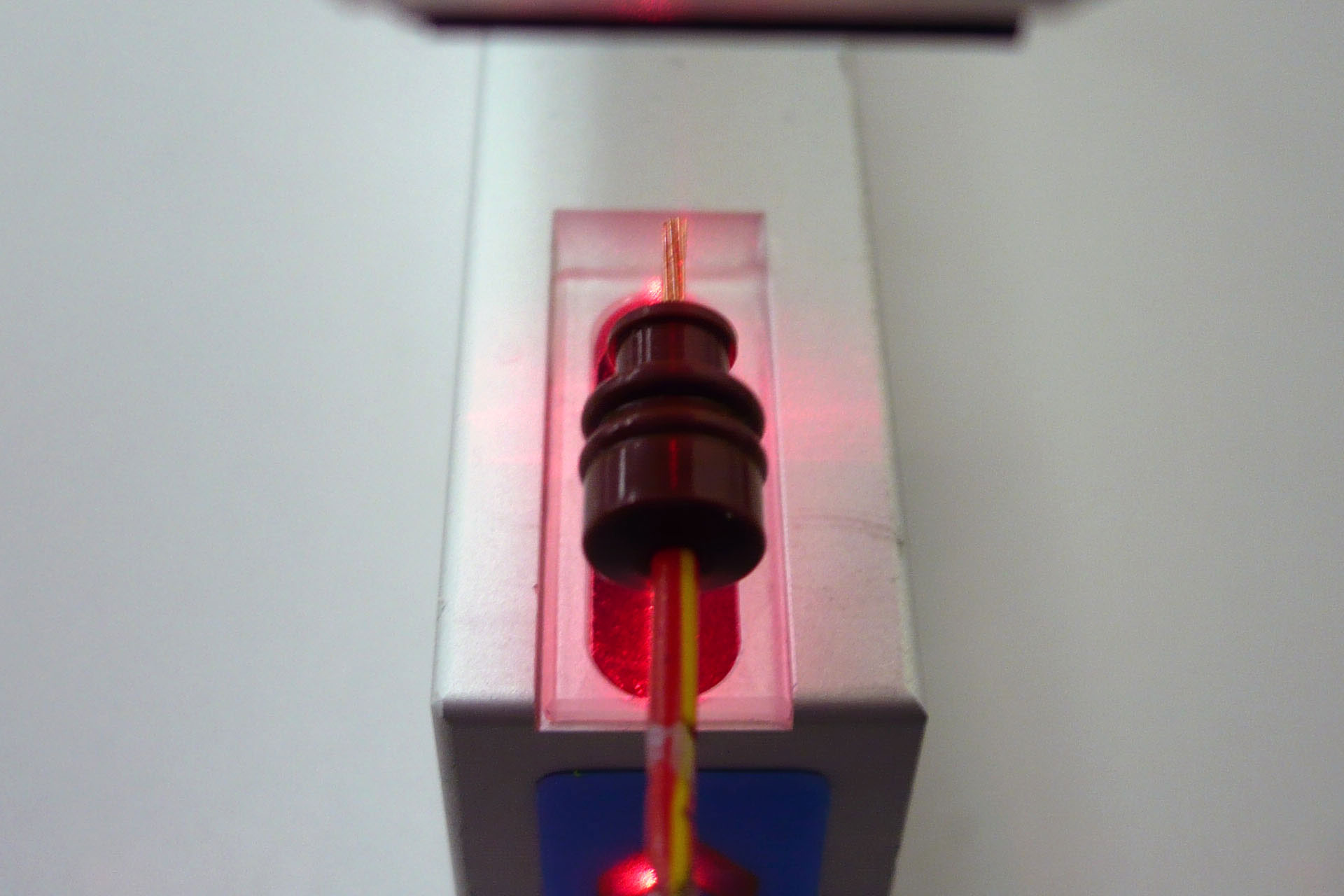

LIS-16 Laser Image sensor

Product details

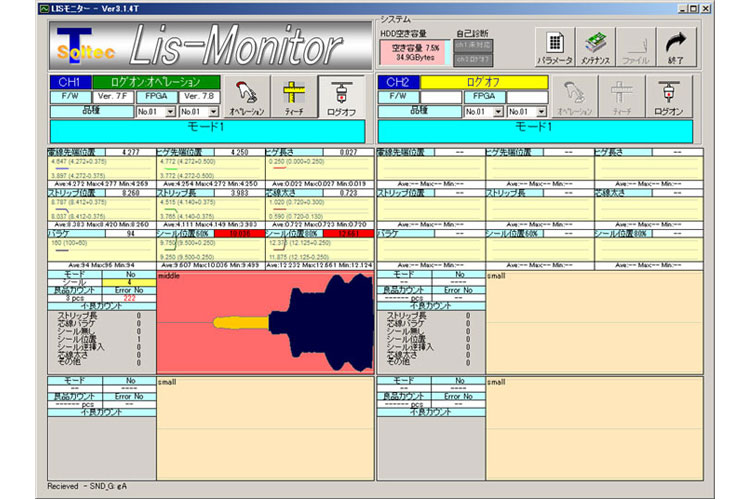

When a stripped wire passes in a laser beam curtain on the feeding route, LIS makes up its proportional image quickly and detects errors such as non-stripping, wire-cutoff, and water protection seal’s insertion error.

Then, the speedy image processing to the proportional image allows performing high level inspections such as measuring stripped length, strands width and detecting end-open, whiskers and so on, which is impossible for conventional sensors to detect.

This system also has functions to automatically correct the image data if a cable is curved, and can perform inspection with high resolution, using sub-pixel processing.

Features

- Self–trigger for measurement

- Easy installation (installable on almost any downsized crimping machines)

- Teaching a good sample only once allows proceeding to inspection.

- With PC, image processing and data save is possible

- Direct access from a server machine through a computer network

Product catalog

Related products

CFM-BL Pro

Crimp Force Monitor BL Pro

CFM-Lite

Crimp Force Monitor Lite

CFM-MX Plus

Crimp Force Monitor MXP

CVM-3

Crimp Vision Monitor

CS07

Cross Section Monitor

PT-X