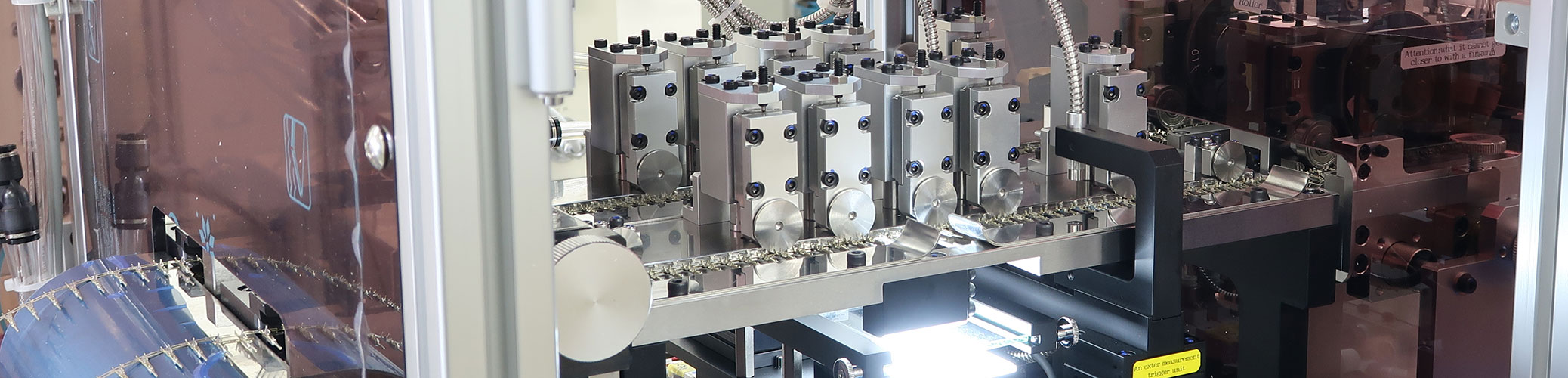

Eye-M03 Match mark image inspection system for injection mold

Product details

Eye-M03 can detect wrong core pins set in an injection mold quickly and surely.

Its high resolution camera captures multiple pictures of the mold surface from various angles with LED lights in order to get clear visible images of engraved match marks on the core pins.

Its software automatically determines whether there should exist any errors among those pictures.

This system prevents users from overlooking mistakes in core pin installation.

In addition, it succeeds drastically in improving operational efficiency.

This is an image inspection device, which is surely going to replace the inspection way conventionally done with humane eye.

We believe that this system is very helpful in your production sites.

About Software

Simple operation

Set the mold tool and enter its registered number to start the inspection.

You can monitor the inspection status because inspected images appear one after another.

Judgment result display

Other than the judgment result, this system can display the position of the core pin judged as error and show both good and bad images.

Inspection image display

The system displays the whole image. You may switch the current inspection point to the other inspection points and also switch the image to the same images captured with other angles of light.

| Model name | Match mark image inspection system for injection mold |

| Part number | Eye-M03 |

| Maximum mold size | 500mm×500mm |

| Target | Hand-written characters, engraved marks by laser, and other kinds of marks |

| Minimum engraved mark size | 1mm2 or larger engraved marks |

| Inspection items | Wrong setting of core pins, omission of core pins |

| Maximum registration number of molds | Approximately 1300 molds (in the case that the capacity of HDD is 2TB) |

| Software | Eyemark Check (Supported OS: Windows10) |

Product catalog

Check out the video for more details!

Related products

TWV-04

Automatic terminal winder for 1 row 4 reels

TSJ-05

100% Inline Terminal Quality Inspection System

MOTER DRIVE

Crimp Terminal Transfer Device for All Inspection

BYW-02