Requesting Main Industry : Manufacture of automotive harnesses

I want to detect a defective crimp that could not be found by visual inspection

Problems we had

Visual inspection results in human error, and defective products flow out to the post-process. Crimp defects that cannot be seen by visual inspection such as core wire breakage crimping is also needed to be detected. The machining stability including the crimp press and die (applicator) should be monitored.

Solving Problems

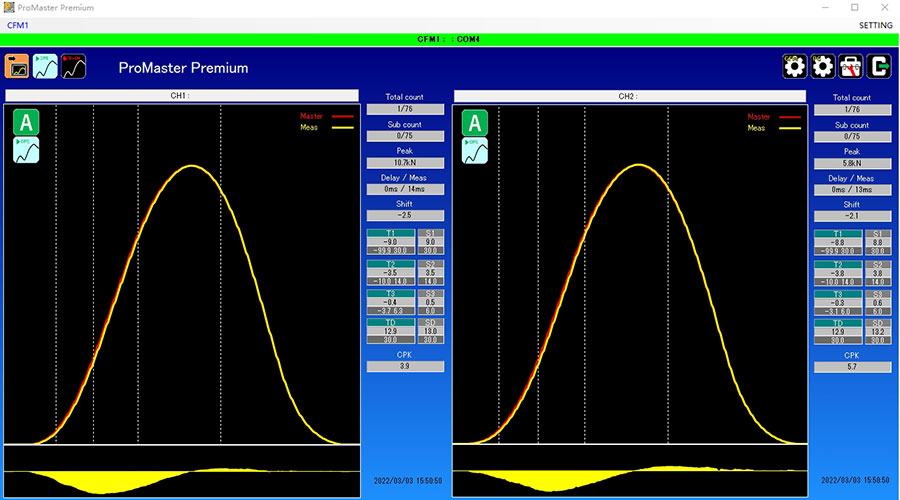

CFM series-using piezoelectric sensors can be mounted on any crimp press. Carrying out the defect inspection which causes the defect crimp and continuity failure of the core wire from the force curve in the pressurization is possible.

Introduced equipment

Other examples of introduction

Industry : Manufacture of automotive harnesses

A non-harmful liquid is needed when performing surface treatment when preparing cross-sectional samples

Industry : Manufacture of automotive harnesses

The Cross-Sectional Sample Preparation Efficiency of Crimping Terminals should and the Crimping Quality should be improved

Industry : Manufacture of automotive harnesses

Measuring the dimensions of the wire peeling length before crimping is needed

Industry : Manufacture of automotive harnesses

A crimp terminal rupture tester that can be pulled at a constant speed is needed

Industry : Production of consumer harnesses